A superior alternative to biodiesel

“Gold Bio-fuel is more fuel efficient then petroleum diesel. Emission of greenhouse gases is negligible of Gold Bio-fuel as compare to petroleum diesel”

Because the limited source of fossil fuel is a big concern for the next generations. Petroleum fuel also causes major pollution issues.

Our research team has invented a new technology for bio fuel. We call it Gold Bio-Fuel.

Some Basic understandings on Bio Diesel:

- Biodiesel refers to a vegetable oil – or animal fat-based diesel fuel consisting of long

chain alkyl (methyl, ethyl, or propyl) esters. Biodiesel is typically made by chemically reacting lipids (e.g.,

vegetable oil, soybean oil, animal fat (tallow) ) with an alcohol producing fatty acid esters. - Biodiesel is meant to be used in standard diesel engines and is thus distinct from the vegetable and waste

oils used to fuel converted diesel engines. Biodiesel can be used alone, or blended with petro diesel in any

proportions. Biodiesel blends can also be used as heating oil. - Space-filling model of methyl linoleate, or linoleic acid methyl ester, a common methyl ester produced from

soybean or canola oil and methanol

The National Biodiesel Board (USA) also has a technical definition of “biodiesel” as a mono-alkyl.

Space-filling model of methyl linoleate, or linoleic acid methyl ester, a common methyl ester produced from soybean or canola oil and methanol

Space-filling model of methyl linoleate, or linoleic acid methyl ester, a common methyl ester produced from soybean or canola oil and methanol

Space-filling model of ethyl stearate, or stearic acid ethyl ester, an ethyl ester produced from soybean or canola oil and ethanol

Space-filling model of ethyl stearate, or stearic acid ethyl ester, an ethyl ester produced from soybean or canola oil and ethanol

Blends:

Blends of biodiesel and conventional hydrocarbon-based diesel are products most commonly distributed for use in the retail diesel fuel marketplace. Much of the world uses a system known as the “B” factor to state the amount of biodiesel in any fuel mix:

- 100% biodiesel is referred to as B100

- 20% biodiesel, 80% petrodiesel is labeled B20

- 5% biodiesel, 95% petrodiesel is labeled B5

- 2% biodiesel, 98% petrodiesel is labeled B2

Blends of 20% biodiesel and lower can be used in diesel equipment with no, or only minor modifications, although certain manufacturers do not extend warranty coverage if equipment is damaged by these blends. The B6 to B20 blends are covered by the ASTM D7467 specification. Biodiesel can also be used in its pure form (B100), but may require certain engine modifications to avoid maintenance and performance problems. Blending B100 with petroleum diesel may be accomplished by:

- Mixing in tanks at manufacturing point prior to delivery to tanker truck

- Splash mixing in the tanker truck (adding specific percentages of biodiesel and petroleum diesel)

- In-line mixing, two components arrive at tanker truck simultaneously.

- Metered pump mixing, petroleum diesel and biodiesel meters are set to X total volume, transfer pump pulls from two points and mix is complete on leaving pump.

Applications:

Biodiesel can be used in pure form (B100) or may be blended with petroleum diesel at any concentration in most injection pump diesel engines. New extreme high-pressure (29,000 psi) common rail engines have strict factory limits of B5 or B20, depending on manufacture] Biodiesel has different solvent properties than petrodiesel, and will degrade natural rubber gaskets and hoses in vehicles (mostly vehicles manufactured before 1992), although these tend to wear out naturally and most likely will have already been replaced with FKM, which is nonreactive to biodiesel. Biodiesel has been known to break down deposits of residue in the fuel lines where petrodiesel has been used. As a result, fuel filters may become clogged with particulates if a quick transition to pure biodiesel is made. Therefore, it is recommended to change the fuel filters on engines and heaters shortly after first switching to a biodiesel blend.

Distribution:

Since the passage of the Energy Policy Act of 2005, biodiesel use has been increasing in the United States. In the UK, the Renewable Transport Fuel Obligation obliges suppliers to include 5% renewable fuel in all transport fuel sold in the UK by 2010. For road diesel, this effectively means 5% biodiesel (B5).

Vehicular use and manufacturer acceptance:

In 2005, Chrysler (then part of DaimlerChrysler) released the Jeep Liberty CRD diesels from the factory into the American market with 5% biodiesel blends, indicating at least partial acceptance of biodiesel as an acceptable diesel fuel additive. In 2007, DaimlerChrysler indicated its intention to increase warranty coverage to 20% biodiesel blends if biofuel quality in the United States can be standardized.

The Volkswagen Group has released a statement indicating that several of its vehicles are compatible with B5 and B100 made from rape seed oil and compatible with the EN 14214 standard. The use of the specified biodiesel type in its cars will not void any warranty.

Mercedes Benz does not allow diesel fuels containing greater than 5% biodiesel (B5) due to concerns about “production shortcomings”. Any damages caused by the use of such non-approved fuels will not be covered by the Mercedes-Benz Limited Warranty.

Starting in 2004, the city of Halifax, Nova Scotia decided to update its bus system to allow the fleet of city buses to run entirely on a fish-oil based biodiesel. This caused the city some initial mechanical issues, but after several years of refining, the entire fleet had successfully been converted.

In 2007, McDonalds of UK announced it would start producing biodiesel from the waste oil byproduct of its restaurants. This fuel would be used to run its fleet.

The 2014 Chevy Cruze Clean Turbo Diesel, direct from the factory, will be rated for up to B20 (blend of 20% biodiesel / 80% regular diesel) biodiesel compatibility

Railway usage

Biodiesel locomotive and its external fuel tank at Mount Washington Cog Railway

British train operating company Virgin Trains claimed to have run the UK’s first “biodiesel train”, which was converted to run on 80% petrodiesel and 20% biodiesel.

The Royal Train on 15 September 2007 completed its first ever journey run on 100% biodiesel fuel supplied by Green Fuels Ltd. His Royal Highness, The Prince of Wales, and Green Fuels managing director, James Hygate, were the first passengers on a train fueled entirely by biodiesel fuel. Since 2007, the Royal Train has operated successfully on B100 (100% biodiesel).

Similarly, a state-owned short-line railroad in eastern Washington ran a test of a 25% biodiesel / 75% petrodiesel blend during the summer of 2008, purchasing fuel from a biodiesel producer sited along the railroad tracks. The train will be powered by biodiesel made in part from canola grown in agricultural regions through which the short line runs.

Also in 2007, Disneyland began running the park trains on B98 (98% biodiesel). The program was discontinued in 2008 due to storage issues, but in January 2009, it was announced that the park would then be running all trains on biodiesel manufactured from its own used cooking oils. This is a change from running the trains on soy-based biodiesel.

In 2007, the historic Mt. Washington Cog Railway added the first biodiesel locomotive to its all-steam locomotive fleet. The fleet has climbed up the western slopes of Mount Washington in New Hampshire since 1868 with a peak vertical climb of 37.4 degrees.

On 8 July 2014,[27] the then Indian Railway Minister D.V. Sadananda Gowda announced in Railway Budget that 5% bio-diesel will be used in Indian Railways’ Diesel Engines.

Aircraft use:

A test flight has been performed by a Czech jet aircraft completely powered on biodiesel. Other recent jet flights using biofuel, however, have been using other types of renewable fuels.

On November 7, 2011 United Airlines flew the world’s first commercial aviation flight on a microbially derived biofuel using Solajet™, Solazyme’s algae-derived renewable jet fuel. The Eco-skies Boeing 737-800 plane was fueled with 40 percent Solajet and 60 percent petroleum-derived jet fuel. The commercial Eco-skies flight 1403 departed from Houston’s IAH airport at 10:30 and landed at Chicago’s ORD airport at 13:03

As a heating oil

Biodiesel can also be used as a heating fuel in domestic and commercial boilers, a mix of heating oil and biofuel which is standardized and taxed slightly differently from diesel fuel used for transportation. Bioheat® fuel is a proprietary blend of biodiesel and traditional heating oil. Bioheat® is a registered trademark of the National Biodiesel Board [NBB] and the National Oilheat Research Alliance [NORA] in the U.S., and Columbia Fuels in Canada). Heating biodiesel is available in various blends. ASTM 396 recognizes blends of up to 5 percent biodiesel as equivalent to pure petroleum heating oil. Blends of higher levels of up to 20% biofuel are used by many consumers. Research is underway to determine whether such blends affect performance.

Older furnaces may contain rubber parts that would be affected by biodiesel’s solvent properties, but can otherwise burn biodiesel without any conversion required. Care must be taken, however, given that varnishes left behind by petrodiesel will be released and can clog pipes- fuel filtering and prompt filter replacement is required. Another approach is to start using biodiesel as a blend, and decreasing the petroleum proportion over time can allow the varnishes to come off more gradually and be less likely to clog. Thanks to its strong solvent properties, however, the furnace is cleaned out and generally becomes more efficient. A technical research paper describes laboratory research and field trials project using pure biodiesel and biodiesel blends as a heating fuel in oil-fired boilers. During the Biodiesel Expo 2006 in the UK, Andrew J. Robertson presented his biodiesel heating oil research from his technical paper and suggested B20 biodiesel could reduce UK household CO2 emissions by 1.5 million tons per year.

A law passed under Massachusetts Governor Deval Patrick requires all home heating diesel in that state to be 2% biofuel by July 1, 2010, and 5% biofuel by 2013. New York City has passed a similar law.

Eco-friendly fuel

Emissions

Biodiesel is the only alternative fuel to successfully complete the EPA’s rigorous emissions and health effects study under the Clean Air Act. Biodiesel provides significantly reduced emissions of carbon monoxide, particulate matter, unburned hydrocarbons, and sulfates compared to petroleum diesel fuel. Additionally, biodiesel reduces emissions of carcinogenic compounds by as much as 85% compared with petrodiesel. When blended with petroleum diesel fuel, these emissions reductions are generally directly proportional to the amount of biodiesel in the blend.

Close Contact Benefits from the “French Fry Fuel”

The reduced particulate and unburned hydrocarbons emissions that result when using biodiesel are a welcome relief in environments where workers and pedestrians are in close proximity to diesel engines, including public transport, mining, and construction. In addition, when high blends of biodiesel are used, the exhaust from diesel engines is often described as smelling like fried food, which aside from causing increased hunger in those nearby, is a welcome relief from the smell of diesel fuel exhaust.

A Clean Alternative Fuel for New and Old Engines

Diesel engines have long had a reputation of being “dirty” engines. However, with the advent of newer diesel engines equipped with exhaust gas recirculation (EGR), particulate filters, and catalytic converters, clean diesel technology provides incredible fuel efficiency with ultra low emissions levels. When coupled with the use of biodiesel, both new and old diesel engines can significantly reduce emissions, including particulate matter (black smoke).

A Closer Look at Emissions Reduction

Studies on biodiesel emissions have been conducted for almost 20 years. In that time biodiesel has undergone the most rigorous testing of any alternative fuel, having been the first and only fuel to be evaluated by the EPA under the Clean Air Act Section 211(b). This study examined the impact of hundreds of regulated and non-regulated exhaust emissions, as

well as the potential health effects of these emissions. Some of these results are summarized below.

| Average Exhaust Emissions for 100% Biodiesel Compared to Petroleum Diesel Fuel* | ||

| Regulated Exhaust Emissions B100 | ||

| Particulate Matter | -47% | |

| Carbon Monoxide | -48% | |

| Total Unburned Hydrocarbons | -67% | |

| Nitrogen Oxides | +/- | |

| Non Regulated Emissions | ||

| Sulfates | -100% | |

| Polycyclic Aromatic Hydrocarbons (PAH) | -80% | |

| Nitrated Polycyclic Aromatic Hydrocarbons (nPAH) | -90% | |

| Speciated Hydrocarbons Ozone Forming Potential | -50% | |

Biofuel Benefits

- Low Price (Economical)

- Less Pollution

- Better Mileage (increase 10%)

- Smooth Engine Running

- Cleans Engine Carbons – Increase Engine Life

- Decrease Maintenance

Technology Description

Raw Material availability: raw material will be available from most of

the part across the globe. Rates are fluctuated but if we consider higher

side rate then also it is viable to process for bio diesel and it’s also

possible in huge quantity.

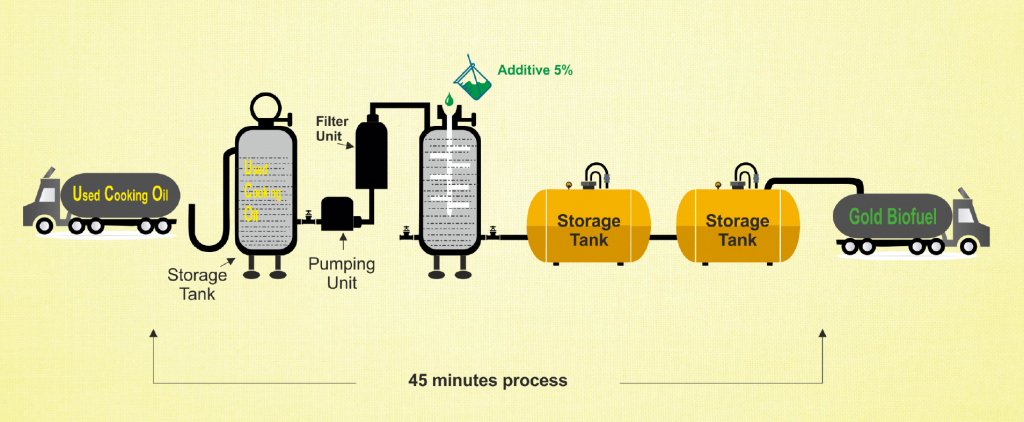

Plant and machinery: Gold bio fuel manufacturing facility

requires minimum no of machinery and space. It’s only needed

only I storage and mixing facility. It will not require huge dead

investment in plant and machinery.

Process: Manufacturing process of gold bio fuel is very simple and fast. Single batch timing is less than 45 minutes. There is no by-product produced during our process. No gas emission during process, no pollution issues.

We can use Gold bio-fuel with 50% blend of petroleum diesel and gradually we can increase proportion of Gold bio-fuel.

Global biofuel policies

Many countries around the world are involved in the growing use and production of biofuels, such as biodiesel, as an alternative energy source to fossil fuels and oil. To foster the biofuel industry, governments have implemented legislations and laws as incentives to reduce oil dependency and to increase the use of renewable energies. Many countries have their own independent policies regarding the taxation and rebate of biodiesel use, import, and production.

Canada

It was required by the Canadian Environmental Protection Act Bill C-33 that by the year 2010, gasoline contained 5% renewable content and that by 2013, diesel and heating oil contained 2% renewable content. The EcoENERGY for Biofuels Program subsidized the production of biodiesel, among other biofuels, via an incentive rate of CAN$0.20 per liter from 2008 to 2010. A decrease of $0.04 will be applied every year following, until the incentive rate reaches $0.06 in 2016. Individual provinces also

have specific legislative measures in regards to biofuel use and production.

United States

The Volumetric Ethanol Excise Tax Credit (VEETC) was the main source of financial support for biofuels, but was scheduled to expire in 2010. Through this act, biodiesel production guaranteed a tax credit of US$1 per gallon produced from virgin oils, and $0.50 per gallon made from recycled oils.Currently soybean oil is being used to produce soybean biodiesel for

many commercial purposes such as blending fuel for transportation sectors.

European Union

The European Union is the greatest producer of biodiesel, with France and Germany being the top producers. To increase the use of biodiesel, there exist policies requiring the blending of biodiesel into fuels, including penalties if those rates are not reached. In France, the goal was to reach 10% integration but plans for that stopped in 2010. As an incentive for the

European Union countries to continue the production of the biofuel, there are tax rebates for specific quotas of biofuel produced. In Germany, the minimum percentage of biodiesel in transport diesel is set at 7% so called “B7”.

Gold Bio fuel Process Diagram

Applications

Gold Bio fuel can be used in a wide variety from cars (old and new), trucks to heavy machinery.

Commercial Viability

Raw Material sources:

We need used cooking oil as major raw material for gold bio fuel, there is abundant sources of use cooking oil worldwide. As per our observation use cooking oil rates are around 200-350 USD/Million tons. It is easy to procure in huge quantity. Process chemicals to convert used oil in to biodiesel is around 100 USD/ 1.000 LITERS. There are no other significant process charges as our manufacturing process is just mixing UCO and our additive. So landing cost of our finish product is very low.

Manufacturing unit:

Our manufacturing plant requires less mechanism because of the simple and time saving process. A plant for 2 Million liters per day will be cost less than 20M USD. Project viability is sure due to less initial investment for plant and machinery.

Recent Comments